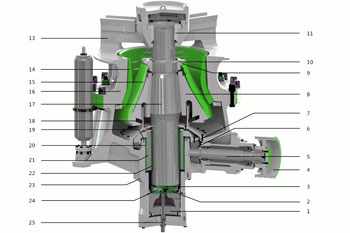

1.hydraulic cylinder 2.lower friction plate 3.upper friction plate 4.pulley 5.countershaft 6.pinion 7.gear 8.head 9.torch ring 10.mantle clamping nut 11.upper main shaft bushing 12.feeding cap 13.tri-arm rack 14.bowliner 15.mantle 16.upper frame 17.main shaft 18.dust sealing ring 19.middle friction ring 20.outer bushing 21.eccentric 22.inner bushing 23.lower frame 24.middle friction plate 25.displacement sensor.

1. Design with deeper crushing cavity optimizes HSC hydraulic cone crusher with more crushing times and higher efficiency.

2. Interparticle crushing works between materials that increases the working life of mantle and bowl liner. Providing more consistent gradation and superior cubic products, better performance in construction and sand making area.

3. Advanced hydraulic technology archives both overload protection and discharge size adjustment, which also simplifies structure and reduces crusher weight.

4. Air cooling system avoids the disadvantage of water cooling system, such as lack of water and leakage of water.

5. Thin oil lubrication, reliable and advanced, increasing service life.

6 .Easy maintenance and operation.

| Model | Cavity Type | Max Feeding Size(mm) | CSS min-max (mm) |

Capacity(TPH) | Power (KW) | Dimension (mm) |

| HSC100 | EC | 240 | 22-38 | 85-170 | 90 | 1535×1275×2710 |

| MC | 200 | 19-32 | 70-130 | |||

| F | 135 | 10-32 | 45-130 | 1540×1280×2300 | ||

| HSC 160 | EC | 360 | 25-54 | 120-345 | 132 | 2045×1635×3040 |

| MC | 300 | 22-48 | 105-305 | |||

| C | 235 | 19-48 | 90-275 | |||

| F | 185 | 13-38 | 66-210 | 2000×1550×2600 | ||

| HSC 250 | EC | 450 | 35-54 | 255-605 | 250 | 2675×2550×3940 |

| MC | 400 | 29-51 | 215-515 | |||

| C | 300 | 25-51 | 190-490 | |||

| F | 215 | 16-44 | 110-395 | 2315×1830×2940 | ||

| HSC 315 | EC | 560 | 41-76 | 335-1050 | 315 | 3110×2945×4480 |

| MC | 500 | 38-70 | 305-895 | |||

| F | 275 | 16-51 | 170-665 | 2740×2200×3590 |

Write a Message